Planning for Code Compliance From Day One in Commercial Kitchen Design

Avoid Redesigns and Delays

Code compliance is one of the most critical factors in the success of a commercial kitchen project. Yet it is also one of the most common areas where projects encounter delays, redesigns, and unexpected costs. When compliance is treated as an afterthought rather than a foundation, restaurant owners and operators often find themselves correcting issues that could have been avoided with proper planning from the start.

Why Early Compliance Planning Matters

Commercial kitchens are subject to multiple layers of regulation. Health departments, fire marshals, building inspectors, and local municipalities all have requirements that influence how a kitchen must be designed and built. These regulations affect everything from ventilation and equipment placement to flooring materials and electrical systems.

When compliance is addressed late in the process, changes can be expensive and disruptive. Walls may need to be opened, equipment relocated, or systems upgraded. Planning for compliance from day one reduces the risk of failed inspections and helps keep projects on schedule.

Health Department Requirements Shape Layout

Health department regulations play a significant role in kitchen design. These rules govern food handling, sanitation, and cross contamination prevention. Layout decisions such as separating raw and cooked food zones, providing adequate handwashing stations, and ensuring proper prep flow are not optional considerations.

Designing with these requirements in mind supports smoother inspections and safer operations. It also helps staff work more efficiently by reducing unnecessary movement and congestion in critical areas.

Fire and Life Safety Considerations

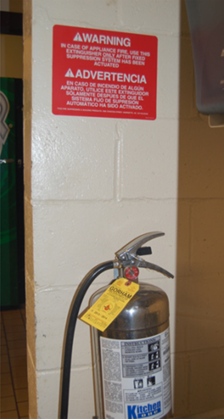

Fire safety is another major component of compliance. Commercial kitchens must meet strict standards for hood systems, fire suppression, and clearances around cooking equipment. These requirements directly influence equipment selection and placement.

Failing to plan for fire code compliance early can result in equipment that does not fit under approved hoods or layouts that violate clearance requirements. Addressing these issues after installation can be costly and time consuming.

Electrical and Plumbing Compliance

Electrical and plumbing systems must also meet code requirements based on load, capacity, and safety. Modern kitchens often require significant power for cooking equipment, refrigeration, and support systems. Improper planning can lead to overloaded circuits or insufficient service capacity.

Plumbing considerations include proper drainage, grease management, and backflow prevention. Designing these systems correctly from the beginning supports compliance and long term reliability.

Ventilation and Airflow

Ventilation is both a safety and comfort issue. Codes regulate airflow rates, exhaust placement, and make up air systems. Proper ventilation helps manage heat, smoke, and grease while supporting a healthier working environment.

A well designed ventilation system that meets code requirements also contributes to equipment longevity and staff comfort. Retrofitting ventilation after construction is one of the most expensive corrections a project can face.

Local Codes and Jurisdictional Differences

Codes are not uniform across all locations. Local jurisdictions may have additional requirements or interpretations that affect design decisions. Understanding these local nuances is essential for successful project execution.

Working with a team that is familiar with regional codes helps prevent surprises during inspections. It also streamlines communication with inspectors and regulatory agencies.

The Advantage of Turnkey Design

A turnkey approach to commercial kitchen design brings compliance considerations into every phase of the project. Design, equipment selection, and construction are coordinated with regulatory requirements in mind.

This integrated process reduces miscommunication and ensures that compliance is not fragmented across multiple vendors. It allows issues to be identified and addressed before they become problems.

Protecting Your Investment

A compliant kitchen is not just about passing inspections. It protects the investment by reducing downtime, minimizing rework, and supporting long term operational success. Compliance driven design creates a kitchen that functions efficiently while meeting regulatory expectations.

Building With Confidence

Planning for code compliance from day one creates confidence throughout the project. It supports smoother approvals, fewer delays, and a faster path to opening.

At Coast 2 Coast Solutions, we approach commercial kitchen design with compliance at the core. By integrating regulatory requirements into every stage of planning and execution, we help restaurant owners move forward with clarity and confidence, knowing their kitchens are built to perform and built to pass.